KLP® Engineered Solutions

KLP® Hybrid Polymer Sleepers:

High-quality ductile polymer, reinforced with steel. Strong, stable, sustainable, recyclable.

Design Intent

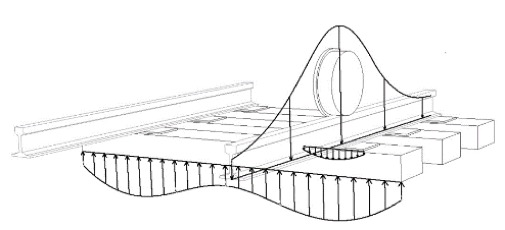

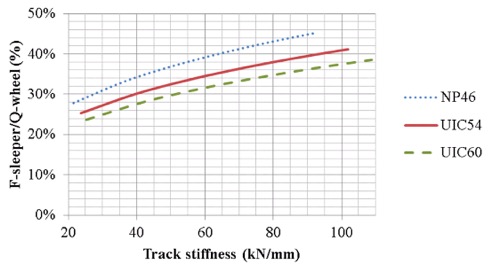

KLP® Hybrid Polymer sleepers are designed to offer an optimum “dynamic track stiffness” that achieves both acceptable levels of bending stress in the rail, as well as good noise and vibration dampening. When KLP® sleepers are used to replace existing sleepers, Lankhorst recommends that the solution should provide comparable stiffness to that of the sleeper it replaces. A very stiff track results in both high impact loads, leading to high wear, premature degradation of ballast and rail-induced vibrations. Too soft a track can lead to fatigue. When interspersing existing track with an alternative sleeper, KLP® can deliver the required continuous track stiffness, as an engineered solution.

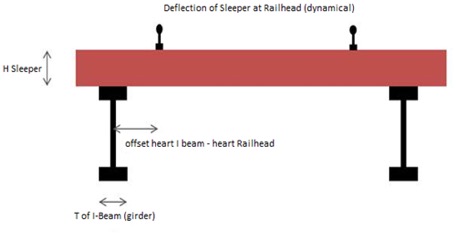

Stable (lateral) gauge control is achieved through the high strength steel reinforcing along the length of the sleeper, providing the required resilience and strength to prevent unintended gauge widening. Refer to the test section for results.

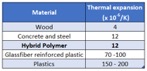

The combination of steel and polymer has a coefficient of thermal expansion close to that of steel and concrete. This ensures stable gauge over the entire temperature spectrum, even more so on bridges, where sleepers are more exposed to direct sunlight.

On-site drilling, milling and customisation is ensured because polymer can be easily machined, like wood.

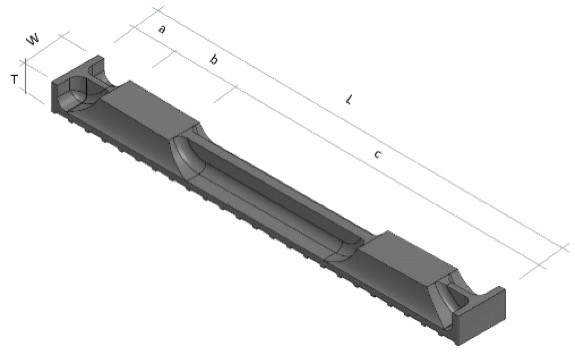

Optimised shape of the mainline sleeper (possible because of the moulding process) reduces the amount of material used (and associated costs), increases vertical stability through the associated ballasting and the change in width achieves extra lateral stability.

KLP® Hybrid Polymer sleepers offer high resilience against environmental factors. Black carbon is added to counter UV degradation. The high strength steel, encapsulated in ductile polymer, is protected against oxidisation, even under extreme load cases. The polymer has high chemical resistance, does not rot nor splinter.

Safety and health are core considerations. Since KLP® Hybrid Polymer Sleepers do not contain fibres, no respiratory equipment is required during machining or installation.

Design Considerations

KLP® products are designed to meet statutory and customer requirement. Upon an expression of interest, or Request for Tender, Lankhorst and Link Asia Pacific will clarify key technical and commercial considerations with the potential client (i.e. axle loads, MTPA and design life, design speed, fastening system to be used, dimensional requirements, number of sleepers required, Type Approval requirements etc.) and then provide a technical solution and commercial offer.

Engineered solutions are developed for specific applications. Contact us for a discussion on the differentiated solutions for main track, switches, bridges, viaducts and tunnels.