KLP® Tested Solutions

KLP® Hybrid Polymer Sleepers:

High-quality ductile polymer, reinforced with steel. Strong, stable, sustainable, recyclable.

Test Philosophy

KLP® products are designed, engineered and tested to meet the specific needs of customers. They are also tested to validate that product design ensures compliance to legal and statutory requirements. In the development of the KLP® Hybrid Polymer concept, Lankhorst realised that comprehensive development, testing and validation by independent and trustworthy institutions would be imperative and essential, to prevent bias, and to establish credibility.

Another unique aspect is that Lankhorst in many cases will test beyond the legal and customer requirements, to determine failure modes under extreme conditions. This ensures thorough understanding of the design intent, and confirmation that modelling and analysis and practical test results correlate with one another.

Lankhorst also ensures that ongoing production ensures quality and maintains the properties established during product development. For this it has developed several in-house test facilities and functions.

Independant and Customer Tests

Various product properties have been tested at a variety of reputable and accredited institutions and clients. Amongst others, these include the Technical University of Munich, Technical University of Prague, University of Vienna, Dutch Movares, Dutch TNO and Dutch Dekra Rail.

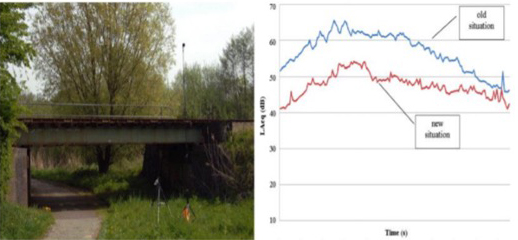

Types of testing conducted include, but are not limited to: endurance, stiffness, 3- point and 4-point bending, dynamic compression, lateral resistance in ballasted condition, coefficient of expansion, vertical uplift, flammability, noise reduction, bonding between steel and polymer, electrical insulation, abrasion test, slip resistance.

Testing has been done at clients and/or legislative bodies like the German Federal Railway Authority and French SNCF to confirm compliance to their requirements.

In-house Testing for Quality Assurance

Test Results

Potential customers are welcome to contact us, for more detailed information on test results.