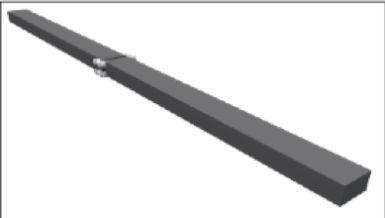

KLP® Switch & Crossing Sleeper

KLP® Hybrid Polymer Sleepers:

High-quality ductile polymer, reinforced with steel. Strong, stable, sustainable, recyclable.

Benefits and Features

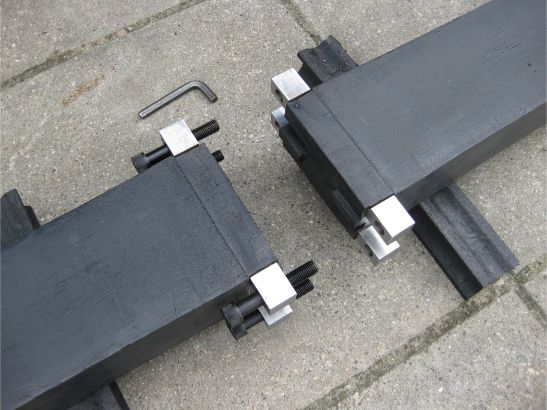

Joining System: The KLP® Hybrid Polymer Sleepers have a unique joining system that allows long members to be supplied. Sleepers can be made into a single member and the joint system allows a turnout member to be twice this length, up to 10.4 m. The connection system allows sleepers to be installed from both sides of the track without excessive excavations.

Low life cycle cost: 50 years design life, nearly maintenance free, savings on replacement and reinstallation costs.

Easy to install: Use same tools as for timber to machine and install, compatible with most fastening systems, no fibre content (no respiratory equipment required). Connectable sleepers can be installed from both sides of the track without excessive excavations.

Durable and sustainable: Steel provides required stiffness, polymer absorbs impact and noise, excellent chemical resistance, electrically insulated, no rot or splintering, moisture and fungus resistant, excellent UV resistance.

Environmentally friendly: Made from 100% recycled polymers, no toxic content, CO2 store, can be 100% recycled.

Diverse application: An excellent alternative to timber, concrete, steel and polymer sleepers.

Sleeper Construction

Four steel rebars: The backbone, offers required strength and bending stiffness.

Connection plates: Cast-in connection plates in order to connect 2 sleepers in-line to a total length of up to 10.4m.

High-quality ductile polymer: Encapsulates the steel bars, dampens impact, vibration and noise.

Dimensions (l x w x h):

2600 x 250 x 150 mm (Type 201/202)

Length as a single sleeper from 2.6 to 5.2 m

Joining system allows any length between 5.2 and 10.4 (type 501/502)

Sleepers can be cut to length on-site or at factory

(Sleepers of alternative dimensions can be developed, contact us).

Weight: 100 – 250 kg

Technical Performance

Axle loads: Ttype 201: up to 25 tonnes, type 202: up to 35 tonnes.

Screw spike pull-out: 46 kN (Type 201)

Installations & Approvals

Germany 2008, 2017

Netherlands 2006 – 2009, 2012 (Light Rail), 2013, 2015