KLP® Sleeper Advantages

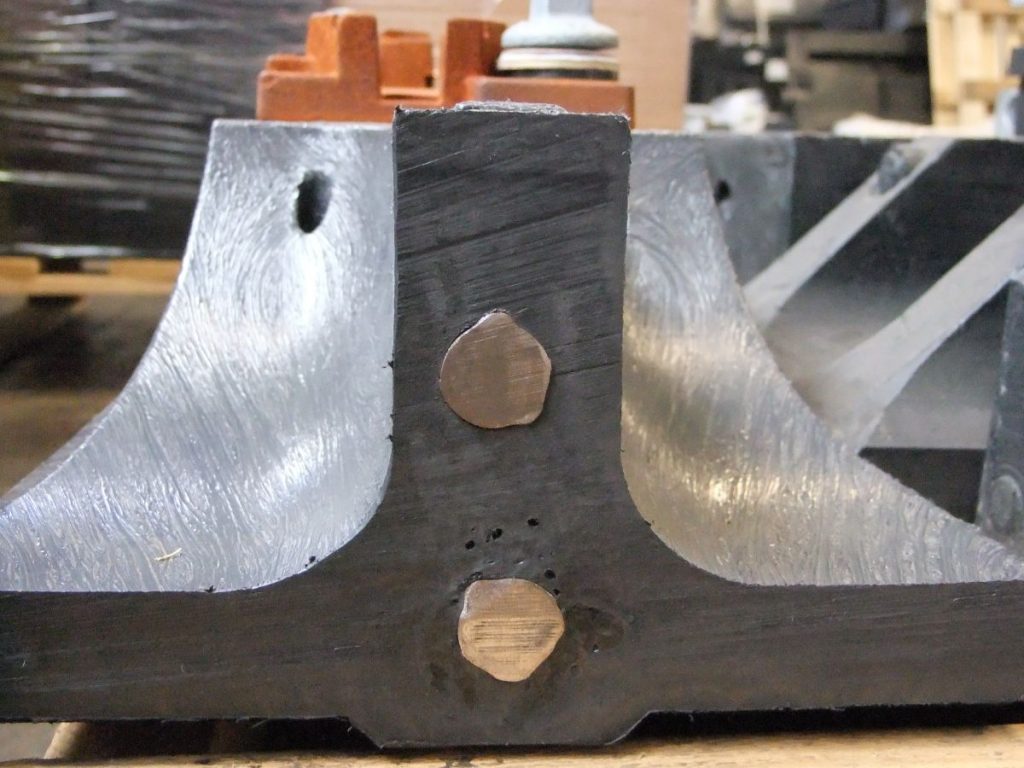

KLP® Hybrid Polymer Sleepers:

High-quality ductile polymer, reinforced with steel. Strong, stable, sustainable, recyclable.

Designed Stiffness

KLP® Hybird Polymer Sleepers are designed to have stiffness comparable to that required or that of sleepers to be replaced

Environmental Friendly

Sleepers are made from 100% recycled polymer material. They contain no softeners, chlorides, cadmium or other environmental harmful additives. They are 100% recyclable. No leaching of unwanted substances.

Electrical Isolation

The sleepers are effectively non-conductive.

Easy to Install

Life Cycle

Design life is 50 years. Timber life ranges between 7 – 20 years. Lower total cost of ownership than timber.

Low Maintenance

Polymers are free from corrosion and insect infestation. Repair process are available should an installation error need to be rectified.

Noise Reduction

Polymer dampens. Reduced noise levels of 3 – 5 dB have been measured.

UV Protection

The sleeper is UV stabilised through the addition of carbon black which prevents material degradation from exposure to UV.

Thermal Expansion

There are different types of sleepers available for different types of climate. The steel reinforcing contains expansion and contraction to 0.15mm, comparable to that of wood.

Quality Control

Lankhorst converts SELECTED polymer waste material to raw materials that are used for production.

Corrosion Resistance

The polymers are chemically resistant to aggressive chemicals and ground conditions. They do not absorb water, rot, corrode, experience concrete degradation or affected by insect infestation.